Revolutionary Dry Process Could Transform Lithium-Ion Battery Performance Forever

Researchers at the University of Chicago have made a breakthrough in battery technology. Their new dry-processed electrode design for lithium-ion batteries challenges traditional manufacturing methods. The discovery could lead to faster-charging, longer-lasting batteries with higher energy density.

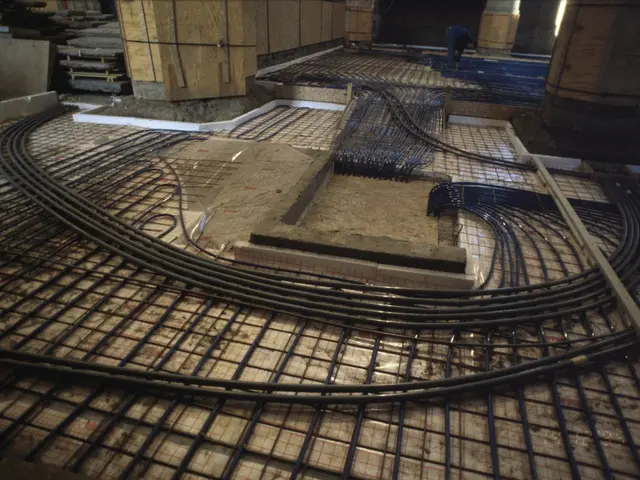

The team at the Pritzker School of Molecular Engineering developed an electrode architecture that skips the usual wet slurry process. Instead, they use a dry method that creates a stronger, more continuous conductive network inside the electrode. This change improves electron flow and overall battery performance.

Tests showed the dry-processed electrodes performed better than expected. The unique mix of carbon-based additives and binder polymers during dry processing boosts both conductivity and durability. The physical structure also helps lithium ions move more efficiently during charging and discharging.

The new approach allows for thicker electrodes with superior conductivity. This could increase the energy density of battery cells, pushing the limits of commercial lithium-ion technology. The researchers aim to refine the method further, targeting batteries that charge faster and last longer under heavy use.

Beyond performance gains, the dry technique offers cost and environmental advantages. It removes the need for solvents and reduces energy use in production. The team hopes to integrate the technology into commercial battery lines, particularly for electric vehicles with extended range and quicker charging.

The discovery opens new possibilities for battery design, encouraging engineers to rethink binder chemistry and electrode microstructure. If scaled successfully, it could transform how lithium-ion batteries are made and used. The focus now shifts to adapting the method for large-scale manufacturing.