Porsche’s New Digital Factory Revolutionizes Battery Cell Production in Record Time

V4Smart, a joint venture between Porsche and Varta, has launched a fully digitalised production facility in Nördlingen. The plant now mass-produces Germany’s first cylindrical battery cells for the automotive industry. Construction and setup were completed in just ten months—a record time for such a project.

The new factory supplies high-performance lithium-ion cells for the Porsche 911 Carrera GTS T-Hybrid. Its production line operates at 80 parts per minute, combining speed with cutting-edge digital technology.

The project began with a greenfield site and an ambitious timeline. MHP, a management and IT consultancy, partnered with V4Smart and Porsche’s Werkzeugbau Gruppe to design the digital infrastructure. Their focus was on creating a lean, scalable system using a cloud-only approach. This accelerated development and showcased the benefits of software-defined manufacturing.

Standardisation played a key role in meeting the tight deadline. Processes were preconfigured and fully integrated with SAP S/4HANA Public Cloud as the central ERP system. Implementation took just ten weeks, ensuring seamless data flow across operations. Automated data quality monitoring also allowed real-time adjustments, reducing inefficiencies and digital waste.

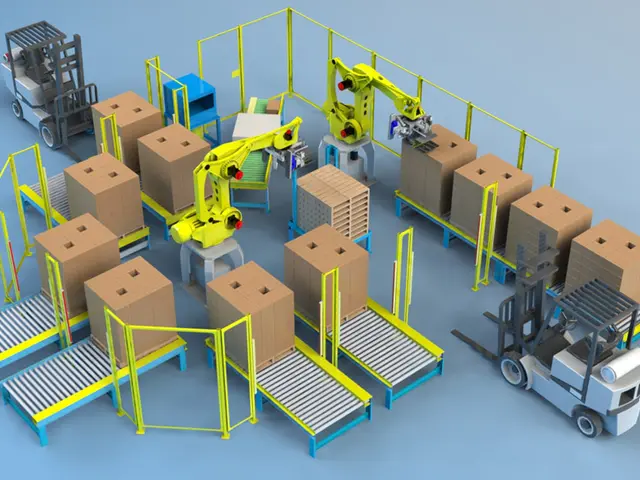

Digital twin technology became central to the factory’s success. It enabled precise control over production from the start, balancing quality and speed. The system’s agility and performance set new benchmarks for innovation in battery cell manufacturing. By April 2025, the facility was fully operational, delivering cells for Porsche’s hybrid vehicles.

The Nördlingen plant marks a milestone in German battery production. Its rapid setup and advanced digital systems demonstrate how software-defined manufacturing can transform industrial processes. The facility now supports Porsche’s hybrid models with high-performance cells, reinforcing the brand’s commitment to innovation and efficiency.

Read also:

- Timberland and Stanley 1913 lead the charge in sustainable take-back programs

- California Water Service upgrades infrastructure with new pipelines and proposes rate hike

- Black Friday slashes MacBook Air and Surface Laptop 7 to record-low prices

- Artist Zainab Odemwingie Launches 'My African Baby' to Preserve Cultural Heritage