How Next-Gen EV Batteries Are Reshaping Electric Vehicle Performance

The battery pack is the heart of every electric vehicle, shaping its range, charging speed, and overall performance. Different chemistries and designs now offer automakers a variety of options, each with distinct strengths and trade-offs. While lithium-ion remains the dominant choice, newer technologies like LMFP and solid-state are beginning to emerge as potential game-changers.

Lithium-ion batteries have long been the standard for electric cars, but their performance varies depending on the cathode chemistry. LFP (Lithium Iron Phosphate) batteries, favoured by BYD and Tesla for mass-market models, are known for safety and durability. They work well for everyday driving but struggle in cold weather and lack the energy density of alternatives.

NMC (Nickel-Manganese-Cobalt) cells dominate the European market due to their high energy density and compact size. However, they require careful thermal management and monitoring to maintain performance. Tesla's NCA (Nickel-Cobalt-Aluminum) batteries deliver long ranges but also need advanced cooling and control systems.

LMFP (Lithium-Manganese-Iron Phosphate) batteries sit between LFP and NMC in cost and range, offering a balanced solution. Despite this, no major automaker currently uses them as a primary option. Geely, which owns Volvo and Polestar, plans to introduce LMFP batteries in production models by 2025, with full-scale manufacturing expected around 2026.

Sodium-ion batteries present another alternative, using cheap and abundant sodium while performing well in low temperatures. Their lower energy density, however, limits their appeal compared to lithium-based options. Meanwhile, solid-state batteries—still in late-stage development—promise faster charging, higher energy density, and improved safety.

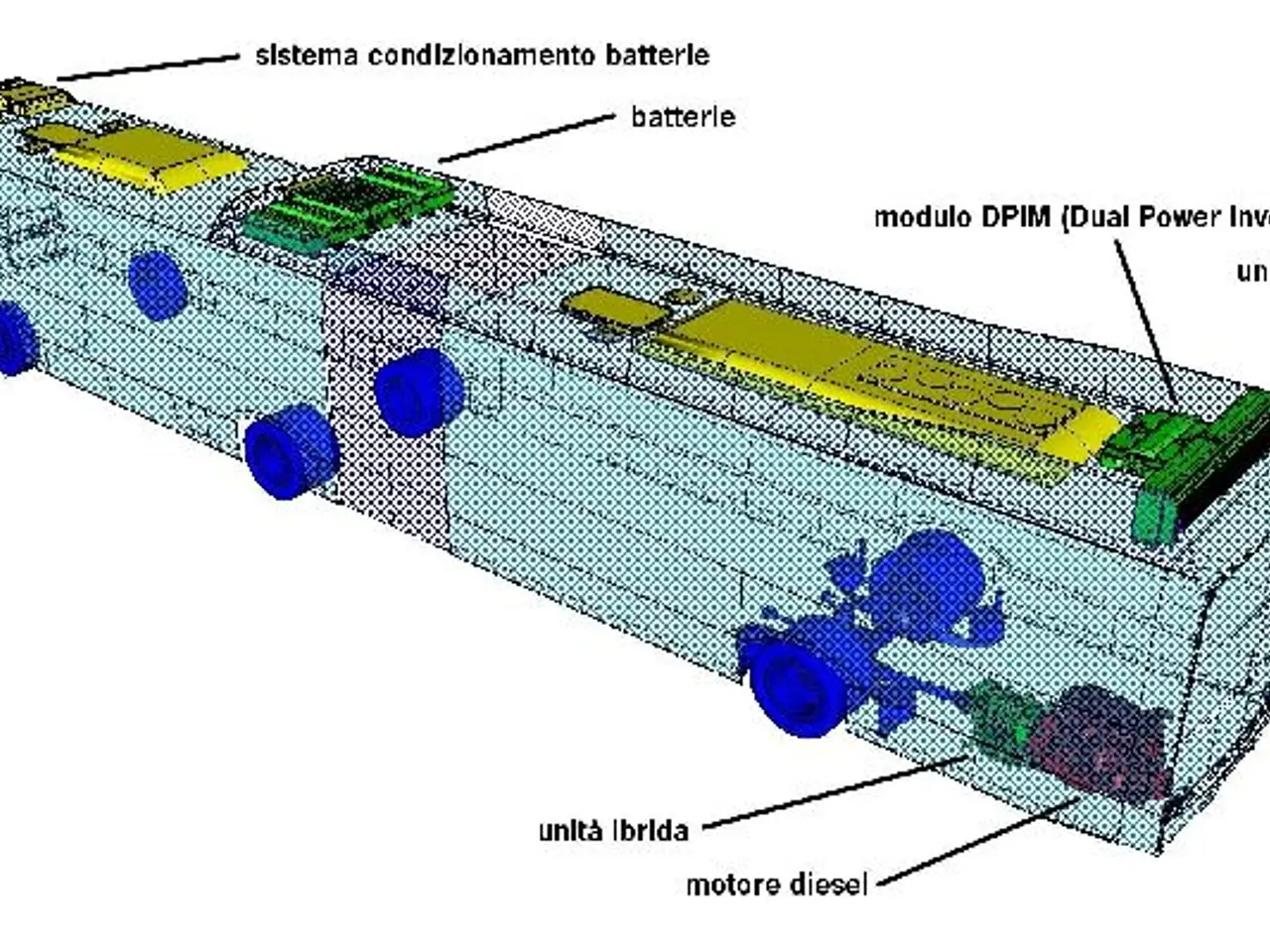

Beyond chemistry, battery design also plays a key role. Cylindrical, prismatic, and pouch cell formats affect weight, rigidity, and energy storage. Structural integration methods, such as cell-to-pack or cell-to-body, further influence efficiency and vehicle performance.

The choice of battery technology directly impacts an electric vehicle's capabilities, from range to charging speed. While lithium-ion remains dominant, emerging options like LMFP and solid-state could soon redefine industry standards. Automakers continue to weigh cost, performance, and safety as they decide which systems to adopt for future models.