GM’s Charlotte warehouse gets a high-tech overhaul for faster, safer operations

General Motors is upgrading its Charlotte Parts Distribution Centre (PDC) with new automation technology. The changes aim to improve efficiency, worker safety and storage capacity. The facility currently handles over 40,000 parts and ships around 420,000 customer orders each month.

David Marsh has taken over as GM’s global vice-president for Customer Care and Aftersales (CCA). He replaces Josh Tavel, who moved to a new role in energy storage and propulsion.

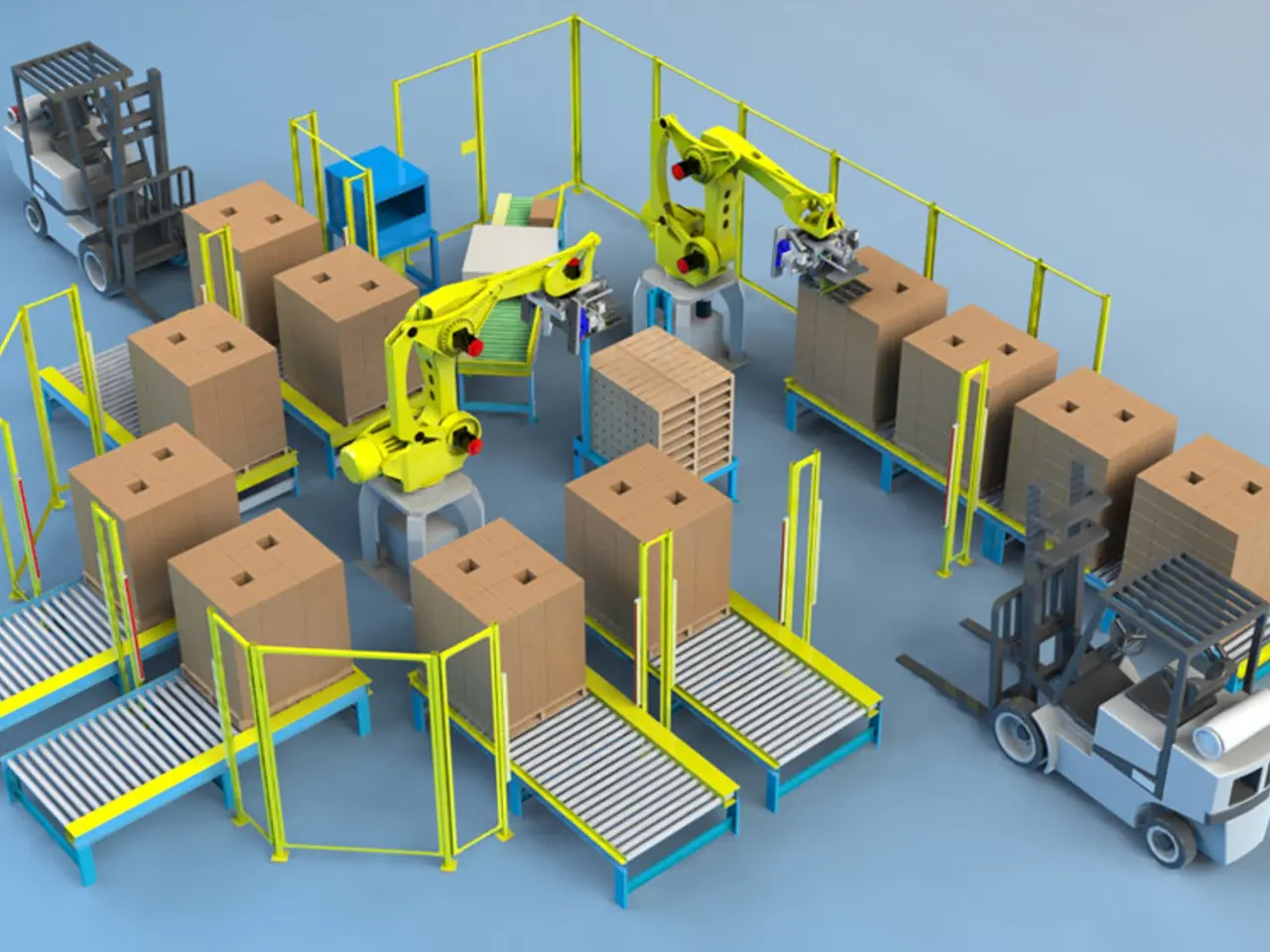

The upgrades will include an automated storage and retrieval system (ASRS) to cut down on manual lifting. This system will also free up 11% more storage space. Autonomous mobile robots (AMRs) will be introduced to speed up order fulfilment.

Additional robotics and conveyance systems will bring sorted materials directly to employees. This reduces the need for walking and repetitive movements, creating a more ergonomic workspace. GM has emphasised that accurate part delivery will remain a priority during the transition.

Work on the new technology will start in June 2024. The full system is expected to be operational by August 2025.

The investment follows GM’s broader push to modernise its facilities. The company aims to meet rising demand while improving workplace safety and efficiency standards.

The Charlotte PDC plays a key role in GM’s supply chain. With over 40,000 parts in stock and hundreds of thousands of monthly shipments, the upgrades will help maintain smooth operations as order volumes grow.

The new automation systems will reduce physical strain on workers and increase storage efficiency. Once fully implemented, the technology is set to improve order processing times. The project reflects GM’s focus on balancing productivity with employee well-being.